Steps And Tips To Use Store Inventory Management System

One of the elements of a successful retail business is inventory management. Using inventory control strategies, physical shops and online sellers can boost customer satisfaction, cut expenses, and grow revenues.

Thus, regardless of retail operation size, all fast-growing retailers or merchants should adopt inventory management software to control enterprise sources better and ease sophisticated procedures.

Once you have a qualified inventory management system, it will be the key to your booming and profitable retail business. The system should allow you to continue delivering products to customers with consistent commodity levels.

![]()

Tracking inventory

In this article, you'll learn about the definition of a store inventory management system, difficulties with stock control, tips for effective retail inventory management, and more. Let's get the ball rolling!

What Is the Store Inventory Management System?

Inventory management is the process of tracking the number of items on the warehouse rack in your store. This method allows you to have the correct number of units in the right location, at the right time, and for the best price.

When you maintain and handle your physical inventory efficiently, you'll know the quantity of each commodity you have, when you're running low on products, and whether you need to restock that item to keep selling it.

You now have a basic knowledge of inventory management concepts and how they affect your routine operations. In a nutshell, inventory management is anything that has an impact on the assets you have available. It's about keeping track of facilities, provisions, stockpiles, and sales.

Inventory management systems (IMS) are sometimes known as retail inventory software or stock management software. They are the tools by which you organize all aspects involved in stock management: products, inventories, orders, and fulfillment to and from customers and suppliers.

In other words, it supports tracking things from one end of your supply chain to the other and keeping an accurate tally of stock levels. With the application of the retail inventory management system, you are fully aware of what items you have, where they are, and how to manage them.

See more: Why Is It Important To Focus On Inventory ConTrol?

Warehouse management software

Arranging goods by category or type, setting minimum quantity requirements, and receiving alerts when inventory levels hit specified limits are among the key functions of an IMS.

Challenges of Store Inventory Control

There are many challenges to inventory management that a retail business owner might encounter. The inventory process includes numerous complex technical parts that must ensure reliable product deliveries to customers. A single mistake in the process can lead to incurred costs and long-term effects that will affect the company's prestige and growth in the long run. Let us go over several of the most common store inventory management challenges.

Issues With The Supply Chain

Global supply chains are dynamic and unpredictable, damaging your inventory management and planning processes. Accordingly, unexpected economic booms and depressions impact raw material availability and prices, affecting most manufacturers and distribution companies.

Apart from this, small-sized enterprises tend to seek the most cost-effective solutions when selecting choices for supply chain activities. Small firms struggle to maintain seamless and ongoing commercial operations when numerous divisions and counterparties are geographically distant.

When workers visit many business units to control stock levels, optimization of warehouse and supply chain management becomes difficult.

Supply chain

Poor Warehouse Space Management

Effective storage facility management is one of the most demanding aspects of any brick-and-mortar retail store. In particular, warehouses must be designed and organized with inventory management systems to control when new products are delivered and make the greatest use of free space.

You must take certain security measures to prevent damage and theft if you own a high-priced inventory.

Warehouse space management is time-consuming and requires several steps, such as receiving stocks, storing them, picking commodities, packing, and shipping them. You need to complete all of these tasks as competently as possible.

Variable Customers’ Demand

Consumer demand is always changing, making inventory storage more difficult.

Customers demand

Keeping too many items may result in outmoded products that you cannot sell, while storing too little may result in an inability to meet customer needs. Order strategies for essentials and technologies for creating and executing an inventory scheme can assist in compensating for fluctuating demand.

Inefficient Communication

Communication and interaction are essential within an organization. When stakeholders or teams are unwilling to share information, recognizing inventory trends and finding possible improvement solutions becomes much more tricky for your business.

Miscommunication can inflict significant harm to efficiency, even in simple commercial processes. Imagine the far-reaching implications for a complex and multifaceted operation like inventory management.

Because inventory management involves many moving parts, clear communication is important to a smooth operation.

Poor communication leads to many problems

Outdated Software or Processes

This issue is most likely the most prevalent and significant inventory difficulty. Many firms still control their inventory using manual techniques or old legacy software, which can stifle your company's growth.

Yet, manual inventory tracking processes require paperwork or tracking processes across many sheets and software, which can result in missing data or data redundancy and take a significant amount of time, along with less safety.

Inventory management software must be integrated with your current business process platforms to accommodate complicated logistics. Besides, choosing from thousands of inventory management systems is a difficult undertaking.

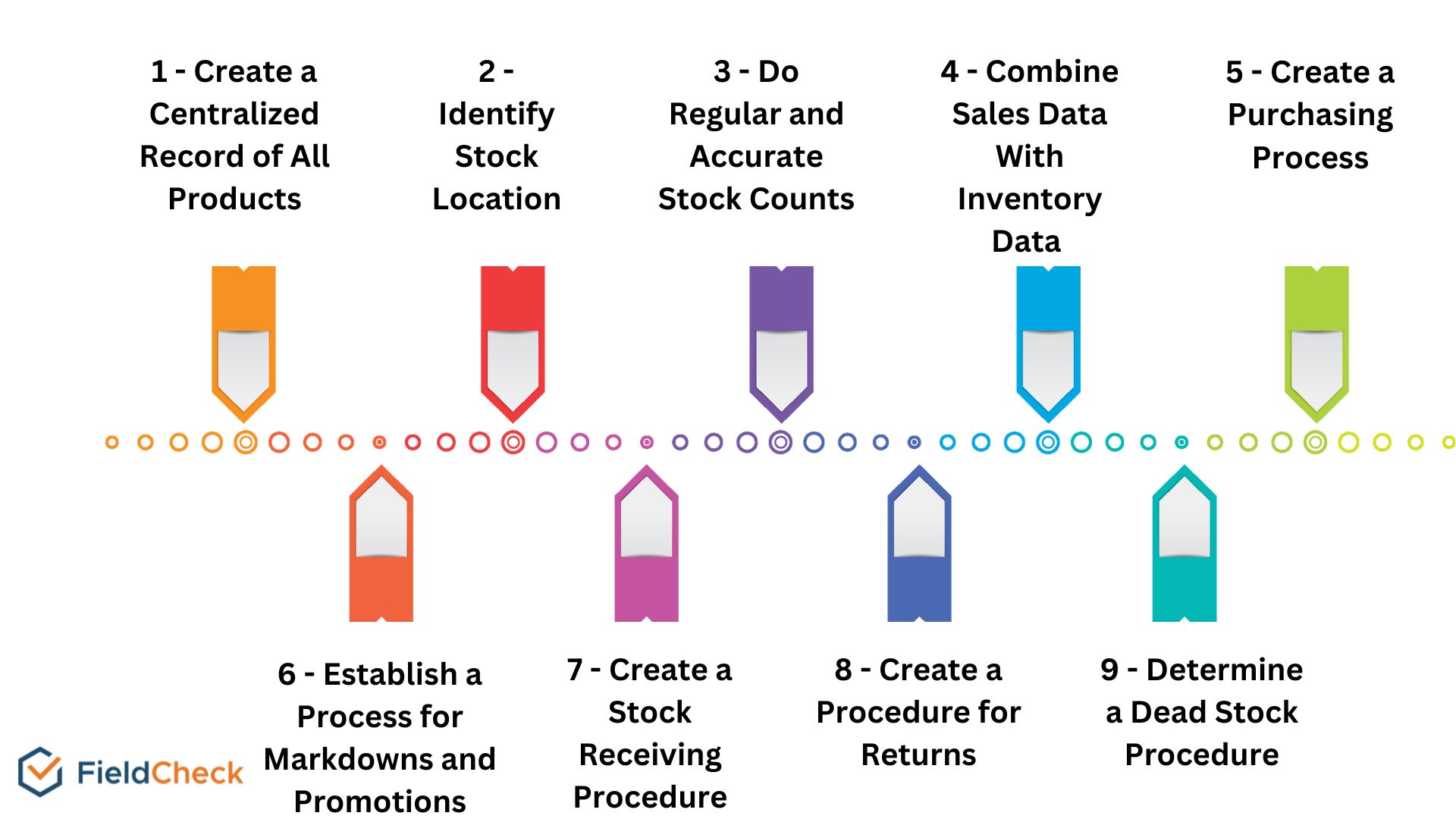

9 Basic Steps in Retail Inventory Management

1. Make A Centralized Inventory of All Products

List all of the items that you offer to buyers in one place with the following information:

- Stock-keeping unit (SKU)

- Product name and classification

- brand, size, lot number, sales price, and expiration date

- Vendor SKU

- Economic order quantity (EOQ)

- Minimum reorder quantity

- Availability of inventory

- Reordering time frame

Then, include product photos and descriptions to assist staff in identifying products. If you sell via e-commerce, this step is critical. Put new products into your inventory when you get them. Collect data such as a vendor's or wholesale cost whenever it changes.

Establish policies for inputting inventory, such as people in charge and expected time to complete it. Holding plenty of data facilitates unlocking the capabilities of a retail inventory control system.

2. Determine Stock Position

If you operate a small company with only one store, tracking the location of your goods is simple. Items are most likely in the storeroom or on display. However, omnichannel retailers and retail chains with several locations may have merchandise in transit, distribution centers, shop shelves, warehouses, or storage rooms.

There are more particular places inside those destinations, such as racks, shelves, and sections. Unnoticed and misplaced merchandise results in lost sales and revenue. Adopting an inventory management system allows you to avoid those problems.

To fully or partially automate inventory mapping, use radio frequency identification (RFID) tags, bar codes, and labels with category and department codes.

3. Do Periodic And Concise Stock Counts

You must count your inventory regularly to maintain its accuracy. To avoid mistakes, account for damage, faults, shrinkage, and returns. A retail inventory control system simplifies this procedure by allowing you to double-check your statistics rather than start from scratch.

As a result, you can concentrate on deviations. It's the frequency of counts that is determined partly by the complexity and scale of your organization. Besides, you can improve a lot with the warehouse management system.

Nonetheless, experts advocate counting inventories at least once a quarter or yearly. Some businesses check individual elements of their stock daily. Physical tracking and cycle counting are two examples of counting techniques.

4. Simplify Reporting by Combining Sales and Inventory Data

A stock management system can combine sales and inventory information. This diagram depicts which goods turnover the fastest and which are underperforming. Use product data to determine when and how much to repurchase and when to offer discounts and promotions.

5. Set up a Purchasing Procedure

An electronic system may establish stock levels for particular items to trigger reorder alerts. Set aside time to review data and arrange purchases, so you don't fall behind on seasonal patterns or risk stock outages.

These levels should contain a buffer that permits purchases to continue at typical levels. If you're utilizing a manual approach, examine whether products are sold out or at reorder points and add them to your list to buy. Prioritize orders based on an item's popularity, lead time, and profitability. Finally, it's time to make a purchase order.

Steps of a retail inventory management system

6. Create a System for Price Cuts and Promotions

Product sales might fall short of expectations for various reasons, including obsolescence, seasonal variables, or cooling trends. If you provide markdowns, be strict about discounting and relocating slow sellers, which can produce cash and free up space for more profitable ones.

Also, you need to create a promotion strategy in advance to guarantee that you have adequate goods on hand to satisfy customer requests.

7. Establish an Inventory Reception Procedure

You will validate incoming orders and precisely record goods in an inventory control system during the handling process. Without a set protocol, any supplier mistake or breakage in transportation can lead to unanticipated stock shortages, overpayment to vendors, and dead stock. Remember to check the contents of each shipment against the purchase order to make sure they are correct.

You may want to put barcodes for price tags on the inventory items based on your demands. The most basic kind of stock control is perpetual inventory management, which entails counting products as soon as they arrive.

8. Create a Returns Procedure

If you don't have an inventory management method for handling client returns, you may risk keeping unmarketable goods or missing an opportunity to restock a sellable item.

When a consumer returns an item, determine whether it is damaged or defective and schedule it for repair, write-off, or refund to the vendor as needed. If the product is sellable, include it in your inventory counts and place it in its proper location (in a warehouse, online store, etc.).

9. Determine a Procedure for Dead Stock

Excess inventory consumes capital and reduces profitability. Damaged commodities, improper delivery, and seasonal products are examples of dead stock. First, list the items in this group and eliminate them from stocks.

Designate a location for dead stock and handle it regularly (weekly, monthly, or as needed for your business). Ship products that you can send back to merchants for credit, known as pullbacks, as soon as possible. Take note of any return shipment deadlines.

Return damaged or defective items to vendors, or record and alert suppliers, as appropriate. Depending on your product line, you can dispose of the excess by selling it to retailers, donating, recycling, or discarding it.

Best Practices for Retail Inventory Management

Expert tips for an ideal inventory management system

Increase Ordering Potency

Do everything possible to ensure you order the right amount of stock at the appropriate time to fulfill customer requests and satisfaction.

This practice includes establishing data-backed standards for your certainty, and par stocks, understanding reorder thresholds, optimizing order sizes with economic order quantity (EOQ), and planning purchases utilizing the open-to-buy technique.

Proactively Manage Your Supply Chain

In this practice, you must share your sales and product projections with vendors and request exact lead times. Monitor service levels from suppliers, such as the proportion of completed orders and completion times.

Communicate with vendors who need to improve and describe the real steps needed to achieve your requirements. It would be best to prepare a contingency plan to identify alternate suppliers for your most necessary items if your principal supplier cannot supply them.

Gather Your Information

Keep an eye on your key performance indicators (KPIs). Using various analyses to determine which goods are your best and worst performers, understand client demand indications and seasonal swings, as well as your high turnover and GMROI.

Attempt to actively increase the accuracy of your client demand and sales projections.

Optimize Productivity

Never stop striving to make every aspect of your stock control more efficient. Structure your warehouse strategically and maintain it neatly. Here are some other methods for increasing efficiency:

- Use the workflow that best fits your order quantity and product categories.

- Store things as close to regions and localities where they are in great demand as feasible.

- Consider whether using drop shipping or a third-party logistics supplier might improve the efficiency of your retail inventory management.

- Reduce shrinkage by implementing loss prevention systems and monitoring incoming items.

- Save all your procedures in files or digital documents following standardization.

Focus On Precision

Conduct routine inventory checks and counts. Set performance goals for employees and train them in merchandise management. Create a culture that rewards the goal of precision.

Employ an Inventory Management System

By employing technology, you can automate numerous tasks and make immediate advances toward objectives such as efficiency and accuracy. By selecting the proper tool, you can combine your POS software with inventory management, removing the necessity for manual data entry and generating richer data.

An automation process can also deliver stock alarm signals and make it easier to coordinate inventory across many sites.

Best practices for the best inventory management system

Why You Should Invest in a Store Inventory Management System

A strong stock management system is indispensable for any retail enterprise, whether physical or e-commerce stores. The most obvious reason is that a retailer cannot keep all their goods in their stores unless they have a large enough space. At the same time, they have a lot of issues with supply distribution across different stores.

Retail merchants must regularly deal with supplies of commodities to be available whenever customers want to buy them. However, the entire process is complicated, involving inventory ordering, sales, transportation, and storage. That's when they need efficient inventory management software to run a lucrative and effective retail business.

This system will automate and handle the difficult aspects of inventory management, freeing up important resources for other aspects of your business.

Stock management tasks

Besides, some other benefits of using an IMS would make you think of adopting one for your operations:

- Fewer missed sales.

- Immediately recognizes changes in inventory levels.

- Reduce stock losses due to erroneous data or tracking systems.

- Lower warehouse expenses.

- Saving time and allowing staff to focus on projects helps company growth.

- Retailers can see stock levels at other sites and remote locations using inventory control software.

- Better serve and satisfy customers.

- Maximize efficiency and profits.

What You Need To Check When Choosing An Inventory Management System

Your inventory tracking software helps you keep track of your inventory as smoothly and accurately as possible. That being said, let's look at the things you should look for when deciding whether a particular system is right for you.

Practical Implementation

Even if you own the best system in the world, it won't be useful if the software is not easy to apply and use.

In other words, you must ensure that implementation has three crucial characteristics: simplicity, speed, and seamlessness.

Good Customer Support

Imagine if you encounter an issue during your trial or application and need support from the provider's team. But when you try to reach them, there's a long queue of people waiting for you, and you are not sure how much time you need to wait.

Customer support service

You might also get frustrated when getting no response from them. As a result, it would be a great idea to make sure you choose a software vendor that provides well-trained, competent, and friendly customer service.

Critical Features

Your company's best inventory monitoring solution is determined by your target audience, business sector, and other considerations.

However, there are several crucial elements of stock management software to look for. Here's a quick breakdown of a number of the most helpful:

- Barcode scanning

- Real-time updates and reports

- Intelligent reporting

- Automation

- Tracking raw materials and assembly processes

- Multi-channel sales assistance

- Goods demand forecasting and planning

- Asset management across multiple warehouses

Barcode scanning

FieldCheck: Store Inventory Management System

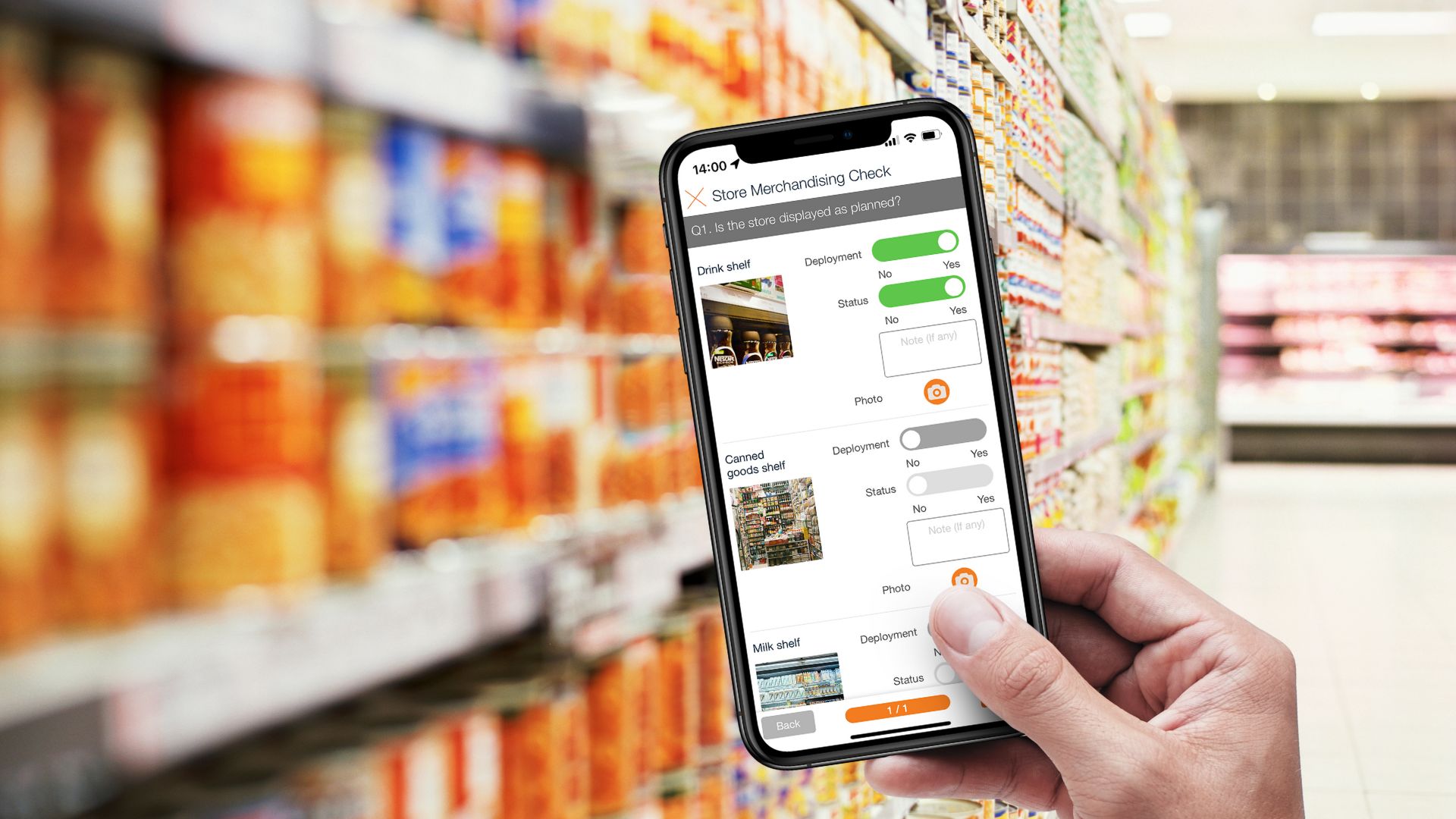

Paper-based checklists make it harder to provide users with outcomes or statistical figures. To address this issue, FieldCheck has created digital checklists linked to the chain management application, enabling managers to track inventory items on their smartphones swiftly and easily.

FieldCheck inventory management solution

When you provide input data such as the name, type, and specification of products on the app, this program lets you record the exact number of available items on hand. Using management software like FieldCheck, you may quickly obtain visual graphs and charts for future usage and actions.

You can save much money on maintenance and downtime by detecting issues during inventory control using the mobile app.

FieldCheck also contains several comprehensive analytical reports on the placement of assets and equipment, allowing you to easily check, compare, and manage the number of them.

Furthermore, the software helps you correctly count the range of devices. If a disparity appears, you may analyze it and determine the source, offering solutions to help cut costs by minimizing inventory.

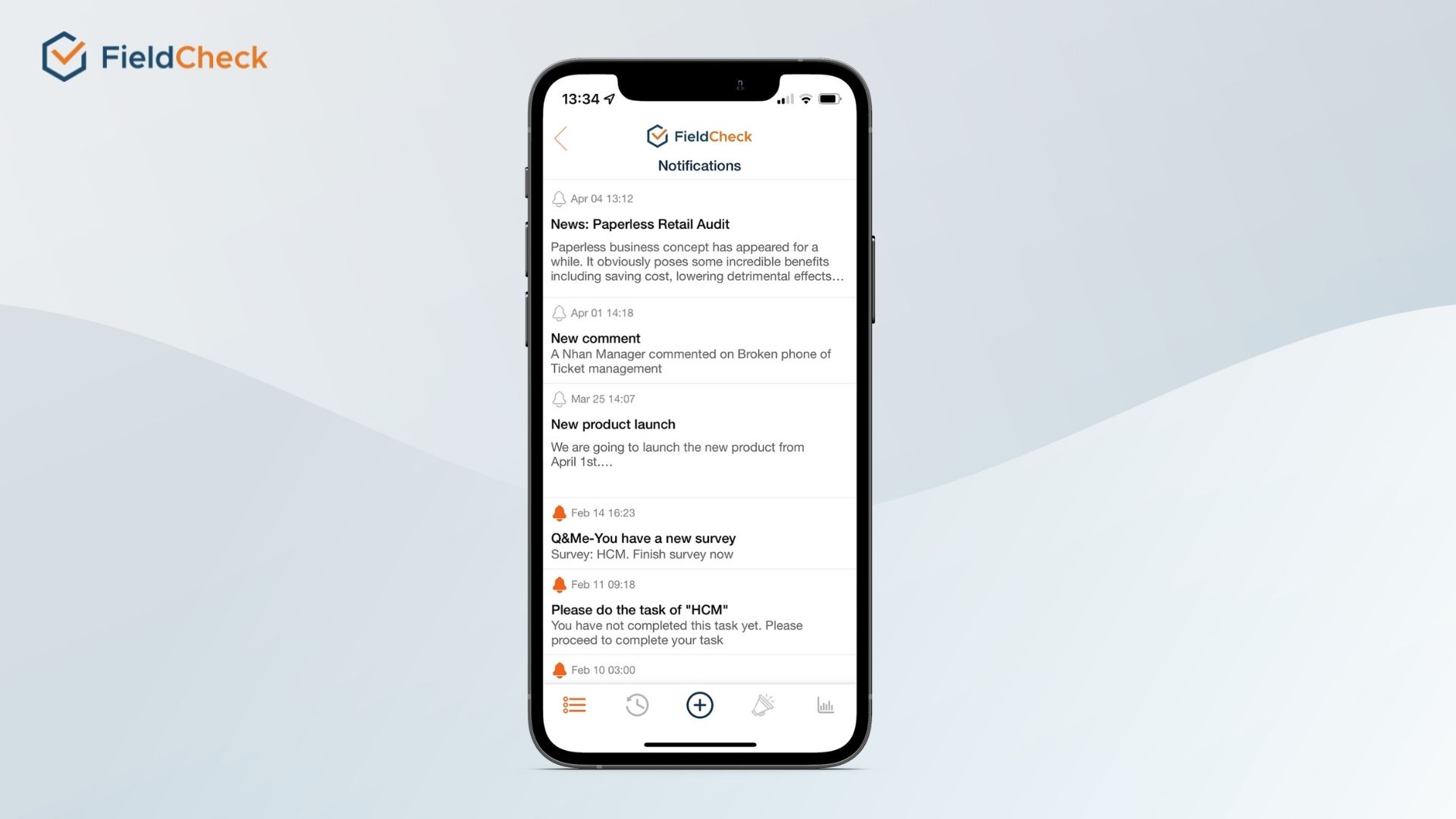

FieldCheck app’s notifications feature

FieldCheck can also provide the following capabilities and benefits on mobile phone devices:

- Daily inventory tracking with a digital checklist.

- Keep a record of your employee's performance.

- Streamline administration and management workflows.

- Orders and purchase requisitions are evaluated and approved.

- Send job notifications to employees that utilize the mobile app.

See more: 8 MOBILE APPS FOR FIELD SERVICE HELPING YOUR TEAMS DO BETTER