What Is PDCA? Today's Most Popular Continuous Improvement Cycle

What is PDCA? The PDCA model is probably no longer strange to businesses of different industry groups, aiming to make improvements in processes and operations. So why is this model so popular?

Let's take a look at some important information about the model that is considered an effective tool for businesses today in the following content.

PDCA model

PDCA model

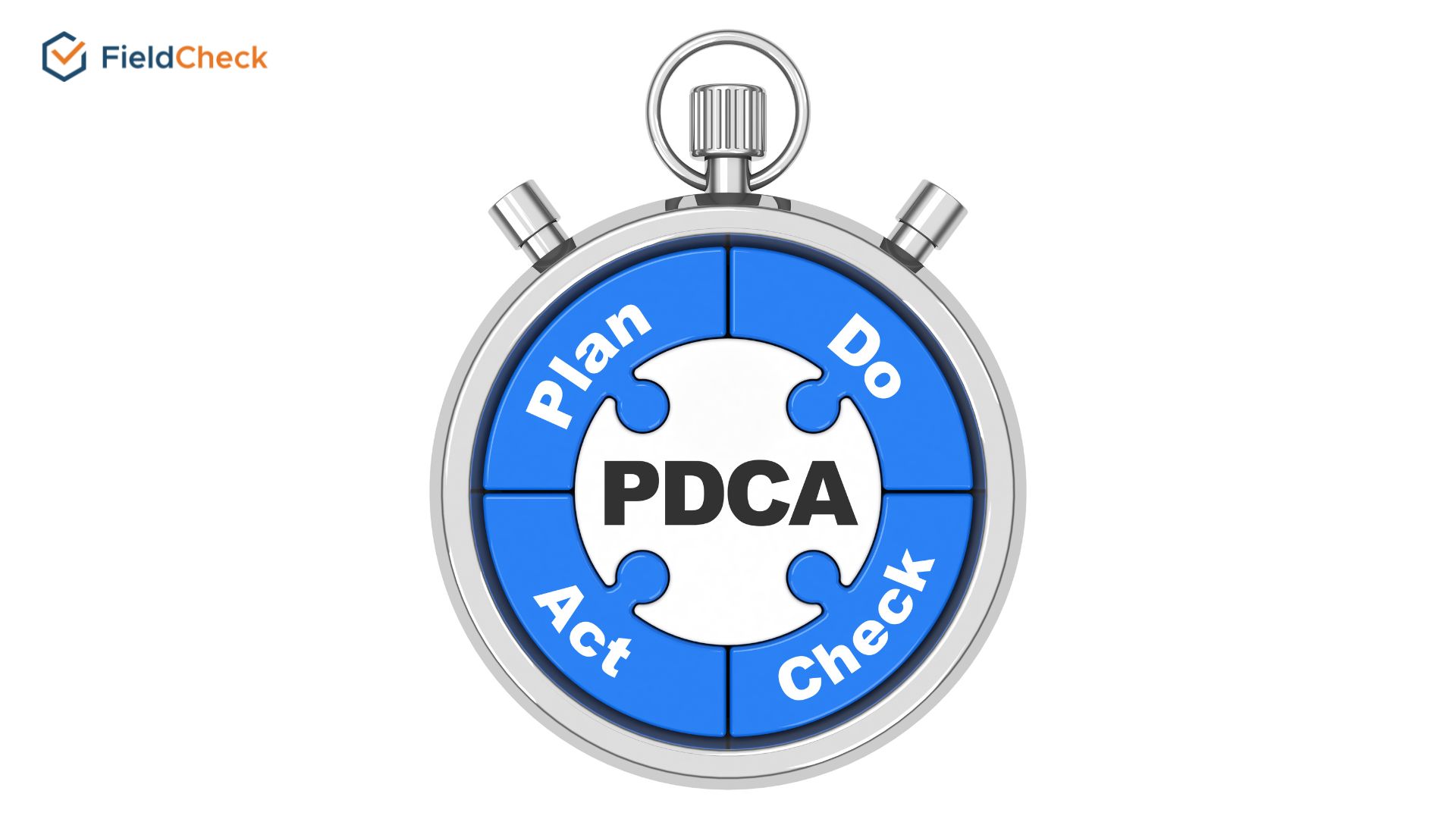

The Concept Of PDCA

What is PDCA? PDCA or Plan - Do - Check - Act represents four tasks that need to be completed sequentially to ensure optimal results.

More specifically, these four jobs are:

- Plan: Build a plan

- Do: Implement the plan

- Check: Evaluate actual results

- Act: Changes and improvements

These four jobs are carried out cyclically and closed. That means PDCA is the cycle from planning, implementing the plan, evaluating the performance and implementing instead to be able to improve the process continuously and specifically for the business.

PDCA: Plan - Do - Check - Act

PDCA: Plan - Do - Check - Act

History of PDCA

Walter A. Shewhart was the first to invent the iterative cycle for improvement, known as the Shewhart cycle:

1. Specify

2. Produce - Produce

3. Inspect - Check

Edward Deming then extended this round of four-step process to Japanese businesses. The Deming cycle is directly and strongly related to the concepts of product quality, innovation, and learning from doing through the life cycle of a product.

In particular, the Deming cycle includes:

1. Design the product with the right testing step

2. Create product and test it in the lab

3. Sell products to the market

4. Test customer experience and redesign for improvement

In 1951, the Union of Japanese Scientists and Engineers replaced Deming's model with the PDCA cycle.

Although more than half a century has passed, most businesses are still using this model quickly and widely, in order to gain feedback from customers and create improvements around the world. market set.

PDCA model for businesses

PDCA Examples

To understand more about the above cycle, you can see the following PDCA example:

- Plan: Organize a program to thank customers

- Do: Implement the gratitude program plan

- Check: Re-evaluate the number of customers of the promotion program, the profits received from the program as well as customer feedback after the program ends.

- Act: Make necessary improvements when implementing promotions, so that the following programs can be implemented better.

Benefits Of The Pdca Cycle For Businesses

This cycle is considered an effective quality management tool today because of the benefits it brings. This is also the basis for making improvements, in order to achieve the end goal set out in the planning step.

The PDCA model helps management levels to monitor and control production and business comprehensively and effectively. Besides, the cycle also encourages businesses to change management methods more effectively.

It also flexibly applies different quality management systems such as ISO 001, 14001, and 22000. Some other benefits for businesses include:

- Improve the working efficiency of employees in the enterprise

- Maintain productivity in process and project monitoring

- Improve the competitiveness of the business compared to other competitors in the industry

Quality management and corporate performance

How Does The PDCA Cycle Work?

This cycle consists of four tasks and is considered the key components applied to quality management and corporate performance.

Step 1: Build a plan

When planning all activities and jobs, businesses should identify the following factors:

- Define specific goals for the planning step

- Identify problems that need to be prevented and resolved

- Identify the processes and actions that should be taken to achieve the objectives

- Identify the resources available or needed to implement the process and action

Step 2: Implement the plan

First, businesses should disseminate the plan established to all departments across the company. Then, depending on the content of the plan, the management of the business can begin to carry out the task in a practical way.

In addition, one of the other important jobs is to collect the necessary data and information during the implementation of the plan. This is considered as one of the bases for future evaluation activities.

The management of the business can begin to carry out the task in a practical way

Step 3: Evaluate the effectiveness of the plan

In this step, businesses should organize an assessment to check and confirm the project progress and at the same time capture details of actual work results or tasks compared with the plan developed in the previous step 1.

In addition, the assessment is intended to detect problems that may arise during implementation. After that, the management level can confirm the cause and influence, and make decisions to deal with it appropriately and quickly and in a timely manner.

Step 4: Implement to improve

Based on the difficulties and problems that will be identified from the evaluation and inspection step, businesses need to develop preventive solutions and solve them effectively and appropriately.

In addition, one of the necessary jobs is to update the data and information needed for the data platform so that it can be used for future activities and projects.

Update the data and information needed for the data platform

Pros And Cons Of PDCA Cycle

The PDCA cycle has some advantages and disadvantages as follows:

Pros

- High flexibility: You can use PDCA in many different business environments with many different applications. Potential use cases include project quality management, change management, product development, and resource management.

- Simple yet powerful: The PDCA model is simple and straightforward, but it is also a powerful tool for making meaningful changes and driving continuous improvement. At the same time, the model also helps to limit the problem of waste and improve operational productivity.

- Kaizen support: The PDCA cycle is a particularly useful tool for companies adopting the Kaizen approach. Kaizen is an organizational mindset and culture that focuses on small changes that often lead to significant improvements over time.

The PDCA cycle supports the Kaizen philosophy by providing a framework for developing and implementing continuous improvements.

PDCA cycle

Cons

- Difficult to implement: Although this model is simple, its implementation in practice is not easy. This is because this model breaks down process improvement into small steps. And the process can be slow and probably won't work for urgent projects.

- Require high persistence: The PDCA cycle is not a one-time use model. It is a continuous and cyclical process. Therefore, this model requires high perseverance from all parties of the business.

Without synchronization and long-term commitment from management to employees, this model will not be able to give the expected results.

PDCA cycle is not a one-time use model

PDCA Application In Quality Management

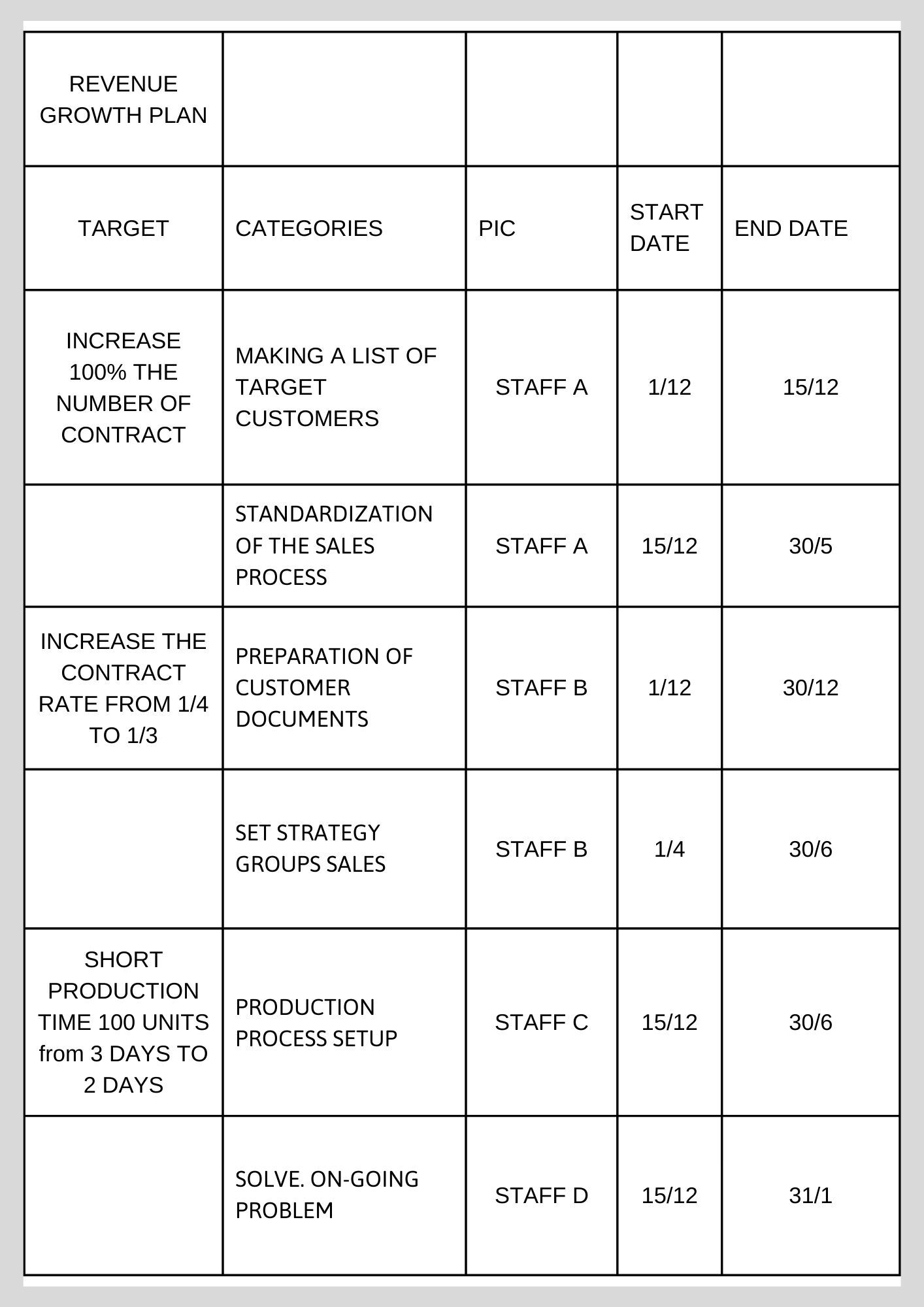

Take the example of a small-scale manufacturing company X, whose revenue mainly comes from supply contracts for small local stores. With the goal of developing and growing at a rate of 100% in 2022, the enterprise has implemented the plan for the PDCA cycle as follows:

One of the important notes is to build an accurate and specific KPI plan. For example, set a KPI to grow 100% of the number of contracts. The number of contracts should also be divided into new and old customer contracts, and the value of each contract is not fixed.

Accordingly, businesses will easily perform detailed follow-up actions based on the available plan. In addition, developing KPIs should be supported by technology software, rather than manual methods. For a small company, doing it manually may not be too much of a hindrance.

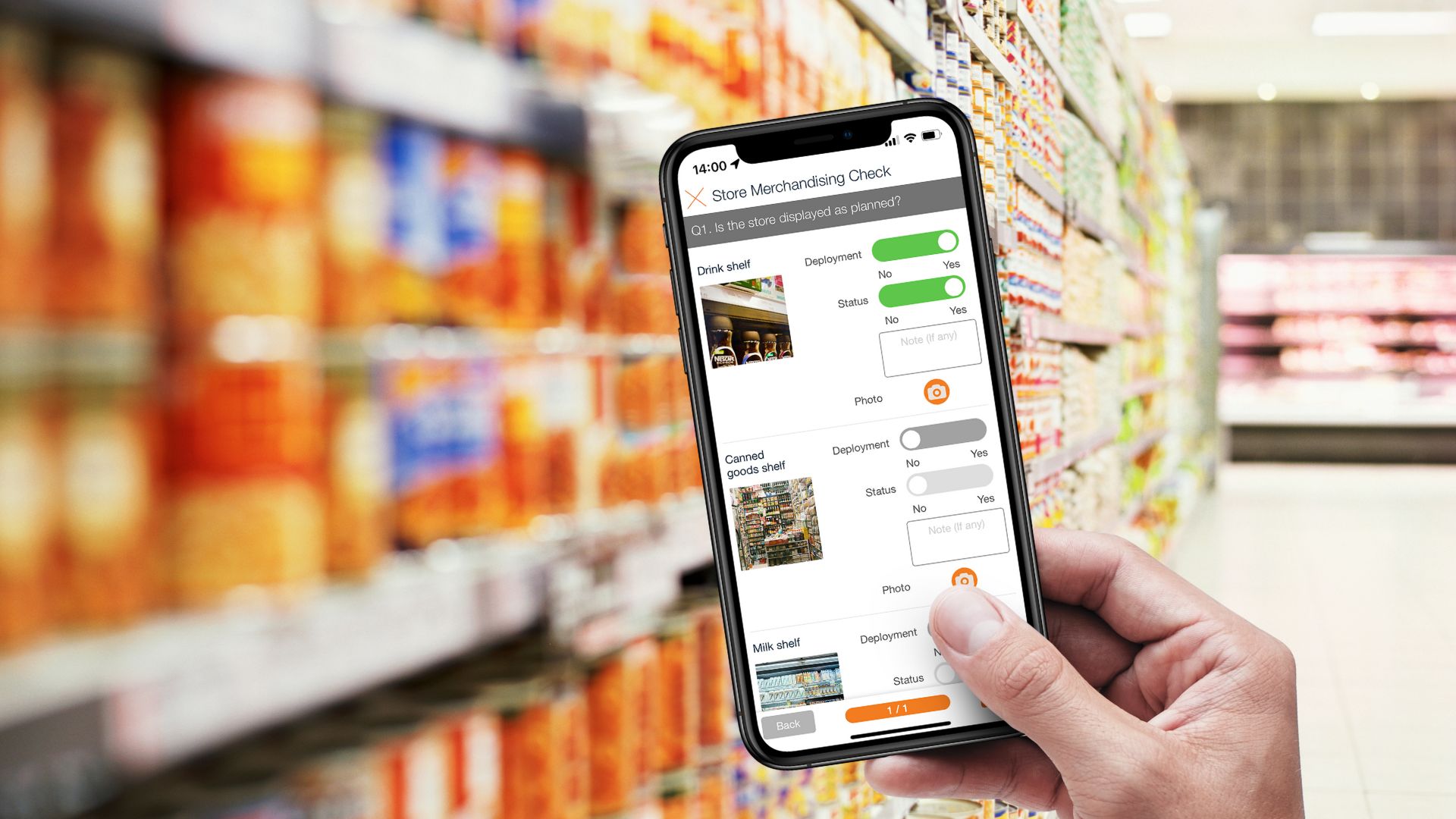

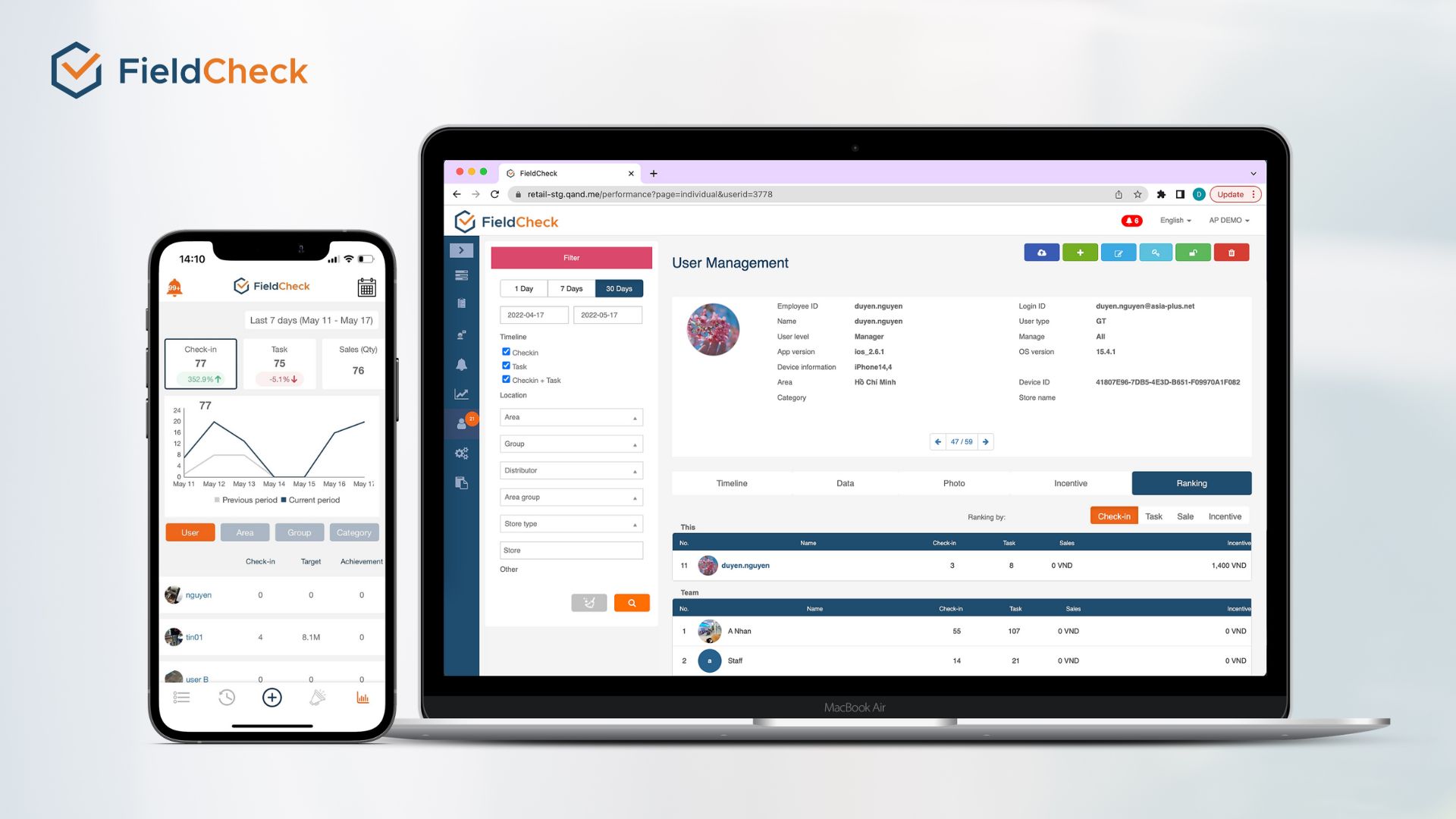

But as the business expands, the level and complexity of targeted governance increases. Applying KPI management software for businesses - for example, FieldCheck is a management level that should not be ignored when managing operational quality in an enterprise.

FieldCheck software with the feature of creating, tracking goals and creating a cycle for KPI

Wrapping Up

Above is some information to help you answer the question, what is PDCA? In general, this model is considered as one of the ways that businesses can make changes to continuously improve their processes as well as their operating apparatus effectively.

There is a saying, “To improve is to change; to be perfect is to change often.” - Winston Churchill."