Supply Chain Management (SCM): Overview & Importance

Supply chain management (SCM) or supply chain process helps businesses manage the flow of products smoothly and efficiently. But how does this model work? Not to mention what is SCM?

It can be said that this is a rather complicated process, and businesses need to study carefully when making strategies. Because if the chain is developed effectively, it will ensure growth in business activities and sustainable development.

For more detailed information, please read the content below!

Supply chain management

What is Supply Chain Management?

Supply chain management (SCM) was initially introduced in the early 80s. Over time, supply chain management has evolved and become an integral part of the operation of the supply chain. So what is a supply chain?

Supply chain refers to the channel structure of inter-agency, out-of-company, inter-company, and retail/wholesale units. Through it, products or services will be introduced to consumers.

Supply chain management helps manage the flow of products/goods and services. This model includes the entire conversion process from importing and processing raw materials to final products.

See more: The recent trends operations management

Elements in the supply chain are closely related

The process is closely related to the results of the enterprise's supplier activities to bring maximum value to customers and simultaneously create a competitive advantage for enterprises in the market.

Accordingly, supply chain management represents the efforts of manufacturers/suppliers to help deploy and develop supply chains, aiming to optimize cost and time.

As you may already know, the supply chain includes activities from production to developing products/systems and the data needed to manage and control this activity.

To summarize, you could take a look below.

- SCM refers to a centralised management of products and services flow. This model includes all processes transforming the first-stage materials to ultimate products and services.

- Thanks to the supply chain management, businesses could eliminate excess expenses and provide products and services to customers more efficiently and faster.

- A great global supply management can keep businesses away from lawsuits and expensive recalls.

- There are five most important components of SCM, including strategy development, raw material sourcing, distribution, returns, and production.

- The managers of supply chains are responsible for controlling, monitoring and cutting costs while avoiding any supply shortages.

How SCM Works

Supply chain management aims to control or link the stages from production to transportation and distribution of goods/products.

SCM model

Effective supply management will help businesses have the ability to optimize costs and time to bring goods to customers.

In an attempt to do that, businesses need to implement processes that can tightly control inventory, production, delivery/distribution, and sales. In theory, most marketed products have been processed in many organizations, forming a complete supply chain.

Although the supply chain has existed for many years, most businesses have only recently focused on it and see it as a form of value-added service in their operations.

In supply chain management, the person responsible for management coordinates logistics from multiple aspects of the chain. This process will consist of 5 parts:

- Strategy or plan

- Source of service or raw material

- Produce according to efficiency or productivity

- Logistics and transportation

- The system handles responses for unwanted or defective products

Management levels of supply chains are working on cutting costs and shortages or excesses of goods/products in the supply chain. This is because this job involves both inventory purchasing and logistics.

The problem of how to effectively manage the supply chain

Like a domino effect, improvements in efficiency and productivity will directly affect corporate profits in the long run. A good SCM will help businesses avoid unnecessary losses from product/goods recall to extremely expensive litigation.

Why is Supply Chain Management So Important?

Supply chain management is important because of the following six reasons:

1. Enhanced Connection

In a supply chain, all actors, from manufacturers, suppliers, warehouses, and consumers, directly influence the operation of the chain.

The above elements connect and exchange continuously and consistently to produce the final product. Besides, supply chain management also solves the problems of increasing market share and developing and expanding cooperation.

The ability to link in the supply chain is very important

2. Integration & Collaboration

A global supply chain is seen as the lifeblood of most of society's needs. Accordingly, the chain needs to operate effectively, right from receiving and entering data to handling problems.

If SCM is not studied and there is close cooperation among stakeholders, SCM will become less effective.

Therefore, even though they operate in different locations, there is a need for regular communication between departments in the company to ensure that everyone understands each other's operational situation.

This action will help enable logistics to cover all activities taking place in the supply chain.

3. Seamless Motion

Aiming to reduce the risk of management of the risks that may occur due to the lack of management capacity, SCM helps to assume the management of the entire logistics operation.

It also helps ensure smooth and seamless operations, streamlining the process from stock generation to unexpected events like natural disasters and epidemics.

Ensure smooth supply chain operations

4. Business Support

When the supply chain goes smoothly, the source of raw materials/products/goods is guaranteed, and the prospects for business development and sustainable development of the enterprise are also enhanced.

In addition, the timely and correct supply of the right goods and quantities will help satisfy the requirements of distributors and manufacturers.

5 Elements of Supply Chain Management

SCM will usually have five main elements as follows:

- Build a plan

- Organize the purchase of raw materials

- Manufacturing

- Delivery/Distribution

- Receive payment

At the planning stage, it is best to have an overall development strategy for the supply chain. The remaining four elements are the primary requirement to proceed with the plan. To have a smooth and efficient supply chain, businesses must improve their expertise in all five factors.

Types of Supply Chain Models

Some current supply chain models:

Continuous Flow Model

This Continuous Flow Model (CFM) belongs to the list of most traditional SCM models. This model helps to provide stability for high demand and low volatility scenarios.

The manufacturer will continuously produce the same product with little change and high stability. The CFM model is common in mature and stable industries.

This model is because these industries have undergone a development period and already have market positions. In addition, these industries have also reached stage 4 in the industry life cycle (Introduction – Growth – Shakeout – Maturity – Decline).

This model helps to increase competitiveness, and businesses can use it to build a continuous replenishment system to ensure good service quality and maintain low inventory levels.

Agile Model

Agile brings great flexibility to enterprise SCM. This is important because it helps the SCM model focus on supply responsiveness for the chain.

The Agile model applies "manufacturing to order", allowing businesses to produce goods after receiving customer orders. This model helps manufacturers reduce the risk of excess stock and increase inventory costs.

If this model is to work well, it needs to be able to help increase capacity in case of large orders while the ability to fulfill orders of smaller batches.

Agile model

Fast Supply Chain Model

The fast supply chain model is especially suitable for fashion manufacturers with short life cycles. That customers in this industry are only interested in businesses with quick product catalog updates to keep up with hot-time trends is attributable to this situation.

Nowadays, the concept of "fast time" is becoming increasingly popular. This term refers to large businesses that apply this method, whether the business is in the fashion business or not.

The desired result is to meet the utilization rate of high-value assets to reduce costs.

Flexible Model

The flexible model allows businesses to meet high demand peaks during peak seasons while also helping to manage time for low-volume, long-distance transportation.

The model is beneficial for industries that experience periods of extreme demand besides short-lived demand (e.g., products for holidays and New Year's Eve).

This model features a high degree of adaptability and the ability to restructure the production process to meet customer requirements. In addition, the flexible model can "turn on and off," - which can be understood more and less easily.

Supply chain management model

Efficiency Model

The model is considered the best for businesses in competitive markets. Businesses that often choose this model produce goods based on expected sales, production cycles, and competitiveness.

Custom Model

As the name suggests, this model can be custom configurable, especially during manufacturing and assembly. The custom model combines the continuous flow model and the Agile model.

So, if the enterprise manufactures products with different configurations, then this model will be the ideal choice. The model also has a high correlation between total costs and assets. It is commonly applied to logistics distributions and downstream logistics (source-limited processes).

The process includes the logistics of getting products into the hands of consumers and customers, including transporting the product from the factory and delivering it directly to the consumer.

Case Study of Effective Supply Chain Management

Walgreens Boots is one of the pioneers in applying SCM in its business apparatus. Enterprises successfully digitalized the entire supply chain in 2016.

Walgreens Boots is the owner of the largest pharmacy chain in the United States. Businesses need to manage their supply chains and correct operational inadequacies to catch trends and continue to increase their profits.

Walgreens Boots

On July 5, 2016, Walgreens also invested in technology for its supply chain management. The company sustainably develops SCM so that it can be used for a long time in the future or, in other words, sustainable development.

Businesses synthesize relevant information and use analytics to predict buying behavior and psychology. For example, a business predicts flu symptoms; thereby, Walgreens can predict the amount of inventory needed for the over-the-counter drug.

Accordingly, businesses can create an optimal supply chain that minimizes inventory. In addition, the application of SCM helps businesses reduce excess inventory and, simultaneously, the entire cost of inventory, transportation, and storage.

Wrapping Up

In short, supply chain management (SCM) or supply chain management will be an attractive industry, attracting many workforces. However, to do this job well requires management levels to be flexible in the way of management and application of the model.

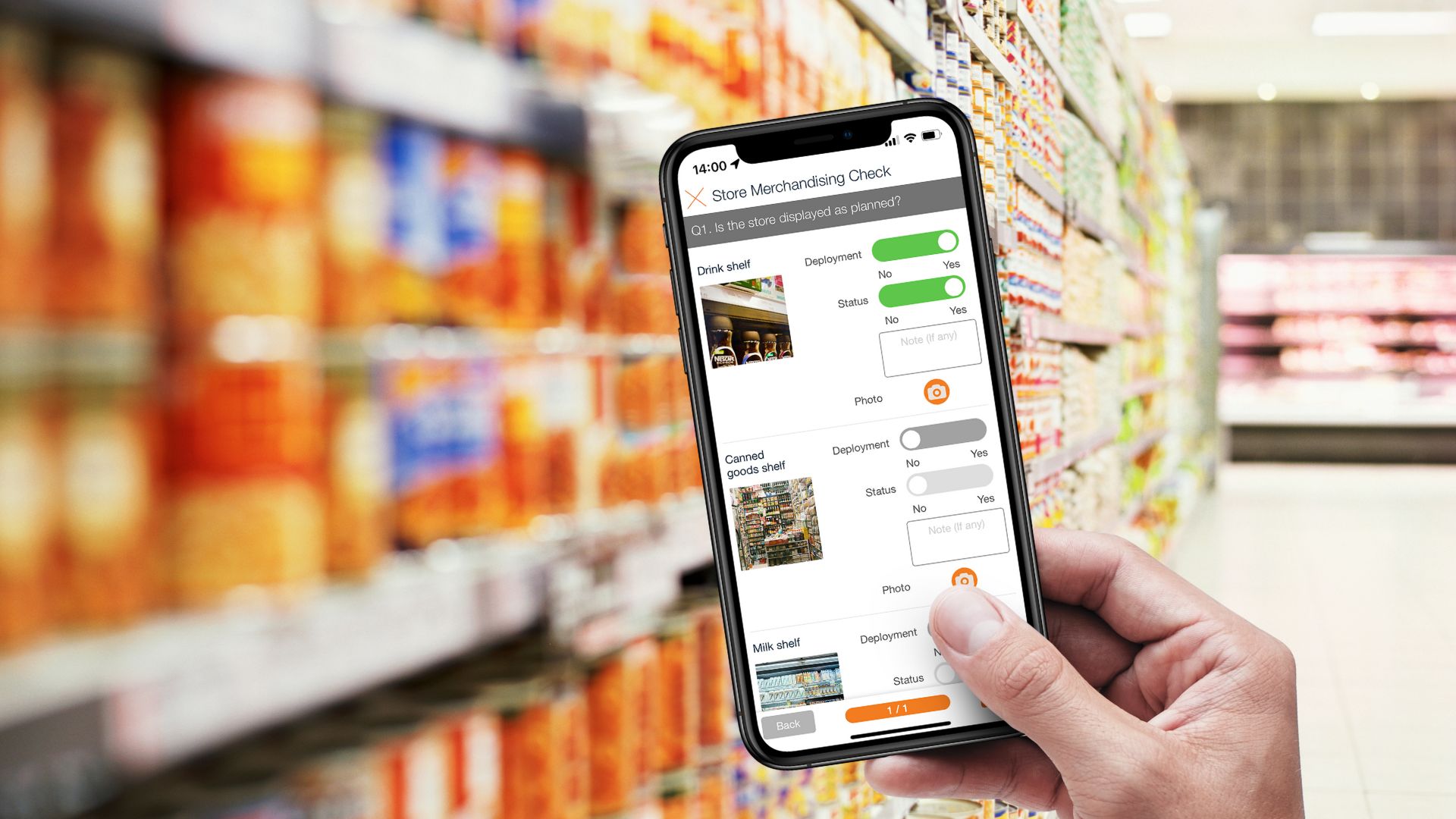

In addition, businesses can use software or mobile applications to support their management.